|

Your position: products > fully-automatic rinser-capper-filler > DGF series for hot drink (tea...) |

||||||

|

¡¡ Fully-auto

rinser-filler-capper |

|

|||||

|

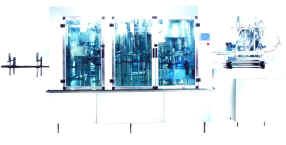

RCGX series Fully-automatic Rinser-Filler-Capper Monoblock for hot filling |

||||||

|

|

||||||

| Model | RCGX16-16-6 | RCGX24-24-6 | RCGX32-32-8 | RCGX40-40-10 | ||

| Production capacity (b/h) | 4000-5000 | 7000-9000 | 10000-12000 | 12000-14000 | ||

| Filling precision | <5mm (liquid level) | |||||

| Feedback consumption | <10% | |||||

| Polyester bottle standard | bottle diameter: 50-95mm, bottle height: 150-320mm | |||||

| way of filling | gravity tiny negative pressure filling | |||||

| gas source pressure (MPa) | 0.6 | |||||

| Gas consumption (m3/min) | 0.2 | 0.4 | 0.5 | 0.55 | ||

| Total Power (KW) | 4.23 | 6.57 | 8.07 | 9.56 | ||

| Total weihgt (Kg) | 3000 | 4200 | 5000 | 5500 | ||

| Dimension (LxWxH) (cm) | 245x170x250 | 320x220x250 | 360x280x250 | 380x300x250 | ||

|

Feature This series of machines integrate washing, filling and capping into one unit, can be used for different kinds of fruit juice/tea hot drink production, with only a few parts changed, the machine can also be used for mineral water filling. 1. The suspending bottle-neck clamping design is used in machine, the filling valves rise and down to fill and let the bottle moving stable. By changing a few parts, can suit for different bottle type. 2. the new generation of stainless steel spring is used in the washing clamps, and the clamps have no contact with the area above the bottle screw. There are many small holes in the washing nozzles, that can wash the whole area inside the bottle. The machine had two outside and inside two stages of washing, guarantee a high clean of the bottle. 3. The advance micro-negative pressure filling technology used in this machine. The filling is quick, steady and accurate. The beverage feed back system is well designed, the gas can be feed back separately, has no contact with beverage, reduce the second time pollution and oxidation. 4. Magnetic torque is used for screw capping, the power of screw capping can be adjusted step-less, it can use constant power to screw capping the plastic caps. 5. The human-machine interface is the touch-screen. The most advanced PLC control and frequency changing technologies are used in this machine. 6. All parts that direct contact with the air made in SUS304 stainless steel. The critical electronic components are from Mitsubishi, Omrom and etc. |

||||||

|

¡¡ |

||||||

| ¡¡ | DGF12-12-4 | DGF16-16-6 | DGF24-24-8 | DGF32-32-10 | ||

| Production capacity | 3000 b/h | 5000 b/h | 9000 b/h | 12000 b/h | ||

| bottle height | 160-300 mm | 160-300 mm | 160-300 mm | 160-300 mm | ||

| bottle diameter | Ø50-90 mm | Ø50-90 mm | Ø50-90 mm | Ø50-90 mm | ||

| Motor power | 1.7 kw | 2.4 kw | 2.4 kw | 3.2 kw | ||

| Dimensions | 196x162x265 cm | 212x176x265 cm | 245x185x265 cm | 295x228x265 cm | ||

| Weight | 2.80 T | 4.00 T | 4.40 T | 5.00 T | ||

|

|

Feature: This series are designed for the polyester-canned hot juice (fruit juice, tea beverages, etc.), employing bottleneck suspending operation and backflow-type canning valve design, resulting in the intergration of bottle-pouring, canning and bottlecap-turning equipments, saving the energy comsumption, reducing the operators, and lowering the possibility of air pollution of juices among the three equipments. the operating speed utilizer the variable frequency control technology. The bottleneck suspending operation design faciliates the change of bottle type: only a few parts are need to change, and then it can be used with atmospheric temperature canning. |

|||||